How BW Transformed Their Site Surveys with the NavLive Scanner

reduction in survey and drawing time

to scan a 8,434ft² office building floor

visibility across design and M&E teams

Meet BW: Workplace Experts

BW is one of the UK and Europe’s leading fit-out specialists, delivering workplace environments for some of the world’s biggest brands. Innovation drives every part of their process, from design to delivery.

The team is constantly exploring new technologies that improve accuracy, speed, and collaboration across disciplines.

The Challenge

Before adopting NavLive, BW’s design and architecture teams relied on traditional survey methods. Slow, labour-intensive, and often requiring multiple site visits to confirm details.

Capturing accurate data could take days, delaying design work and complicating coordination between disciplines. For a company built on innovation, this manual process was holding them back.

When BW first encountered NavLive, there was understandable scepticism. Could a handheld scanner truly match the accuracy of a full survey team, and deliver results fast enough to change established workflows?

The Solution

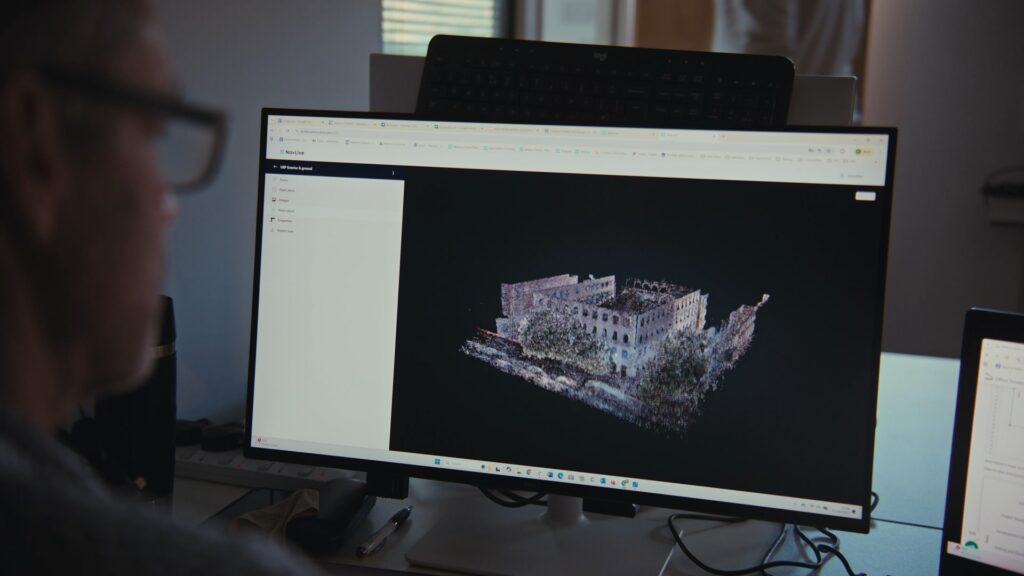

Built specifically for the built environment, the NavLive Scanner combines LiDAR sensors, high-resolution cameras, and on-board AI to capture and process spatial data in real time.

As the user walks through a space, the device automatically generates detailed 3D models and 2D floor plans, giving instant, visual feedback and eliminating guesswork.

Once BW trialled NavLive on a live project, the results were immediate.

At one London office for a leading global private bank, the team scanned an 8,434ft² floor in just 10 minutes, with a complete Revit model ready within two hours. A process that once took days was now completed before lunch.

By producing both point-cloud data and photographic context in a single pass, NavLive gave BW a unified, verifiable record of every project. Designers could collect everything they needed in one visit and share it instantly with M&E teams, transforming how information moved through the company.

The Impact

NavLive has quickly become an integral part of BW’s design workflow. What began as an experiment is now a standard practice across their projects in the UK and abroad.

With all data captured in a single scan, designers can model with total confidence. Coordination with M&E teams is seamless, errors are reduced, and every stakeholder works from the same verified information.

Even international projects benefit. One visit captures everything, removing the need for repeat travel or missing measurements.

The Results

Since adopting NavLive, BW has cut survey and drawing time by around 80%.

Spaces that once took days to measure and model are now captured in under an hour, with fully coordinated 3D and 2D outputs ready the same day.

This shift has transformed how BW approaches project delivery. A single scan replaces multiple site visits, design teams collaborate in real time, and every discipline has full visibility from day one.

For BW, NavLive has not just improved efficiency. It’s redefined what “as-built” means in modern workplace design.